WE LOVE TO GROW

Strain Selection and R&D

We are dedicated to a lifelong pursuit of improving our craft and refining our strain offering to excite palettes and satisfy distinguished cannabis cravings. We pheno hunt to secure desirable effects, pleasant flavor and a good fit within our cultivation system. Good in – good out means we progressively examine nutrient lines and our IPM to acclimate and improve results with our evolving strain roster. Whether it is flavor, effects or lifestyle solutions we carry cannabis that resonates with our customers.

Growing Medium

Our cannabis grows in a soil-less medium of peat and perlite- PH adjusted to our liking for ideal nutrient uptake. This provides our plants with a neutral growth medium to encourage a healthy and pest free root system. We emphasize cultural control for pest | pathogen management and replicate naturally occurring environments to promote the optimal relationship between plant and soil.

Hand Watering

We hand water our plants daily. This gives us the chance to assess each plant individually for optimum nutrient and water uptake.

Hand Manicuring

The garden team prunes our plants several times throughout their vegetative and flowering cycles. Plants are defoliated and supported with trellis netting to control their energy and architecture in order to produce the healthiest buds.

Hand Harvesting

Each plant is harvested delicately by hand for favorable yield and detailed flower inspection. On a weekly indoor harvest schedule, we provide consistency of our product in both quality and quantity.

Drying

Once harvested, branches are hung on lines to dry in a dark, cold and humidity-controlled environment. They spend up to a week drying on lines and are then moved to bulk drying totes to slow the drying process. They remain in darkness and nippy temperature in preparation for trim.

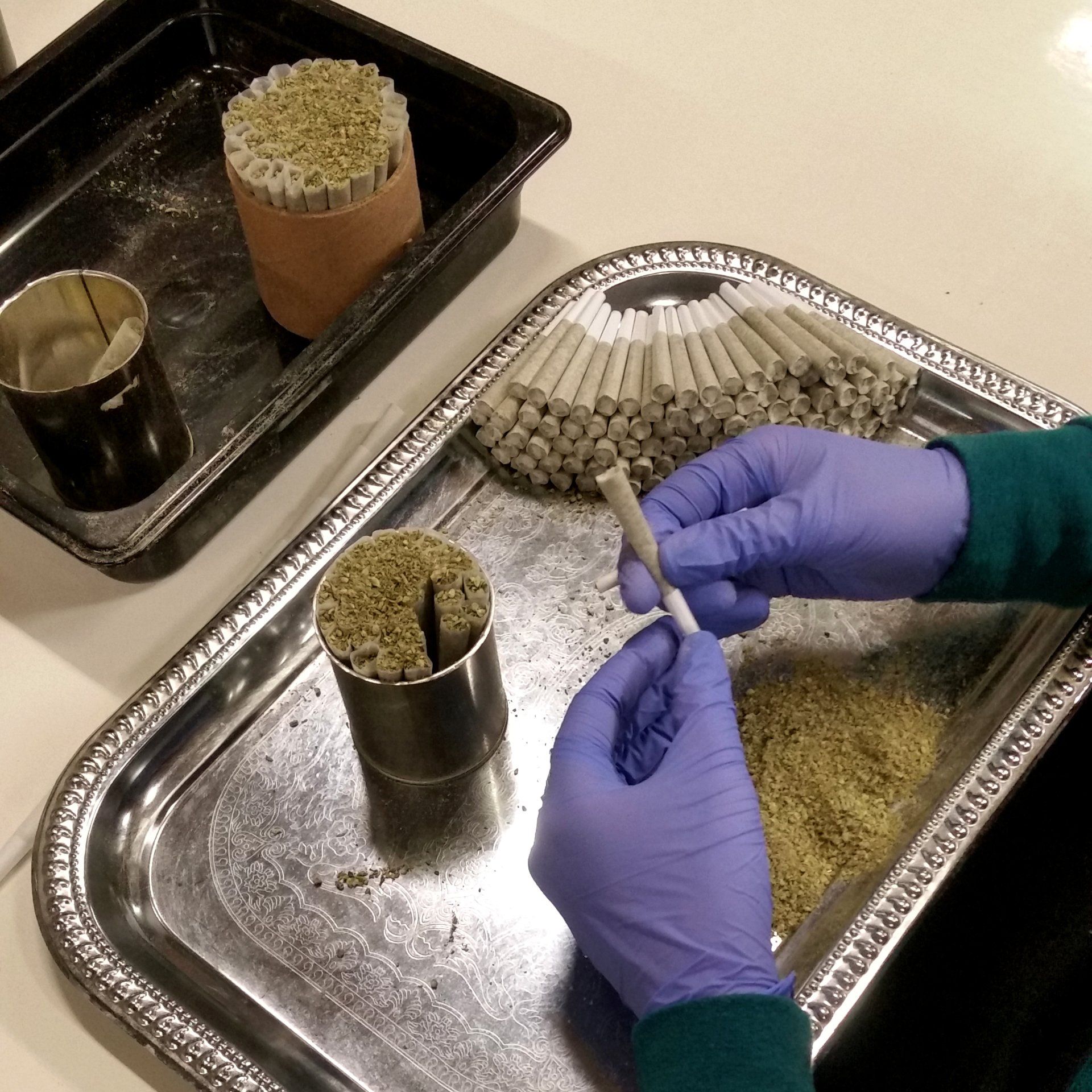

Hand Trimming

Our harvest team hand trims every plant with care allowing for thorough flower inspection. The process ensures quality, desirable texture and checks for gardening concerns. Every flower is trimmed for appeal and value with minimal stem and leaf material. Our standards require only the healthiest ample buds be processed for premium packaging with remaining material going to joints.

Curing

After trim, our buds continue their cure in a separately contained and similarly dark, cold humidity-controlled environment. The home stretch involves continuing to retain adequate moisture and preserving terpenes, essential source of aroma, flavor and in part potency. In concert, we want to allow ample time for chlorophyll breakdown into sugar. A proper cure will produce a smooth smoke, increased potency, powerful aroma and more importantly pronounced flavor.

Hand Packaging